Lean

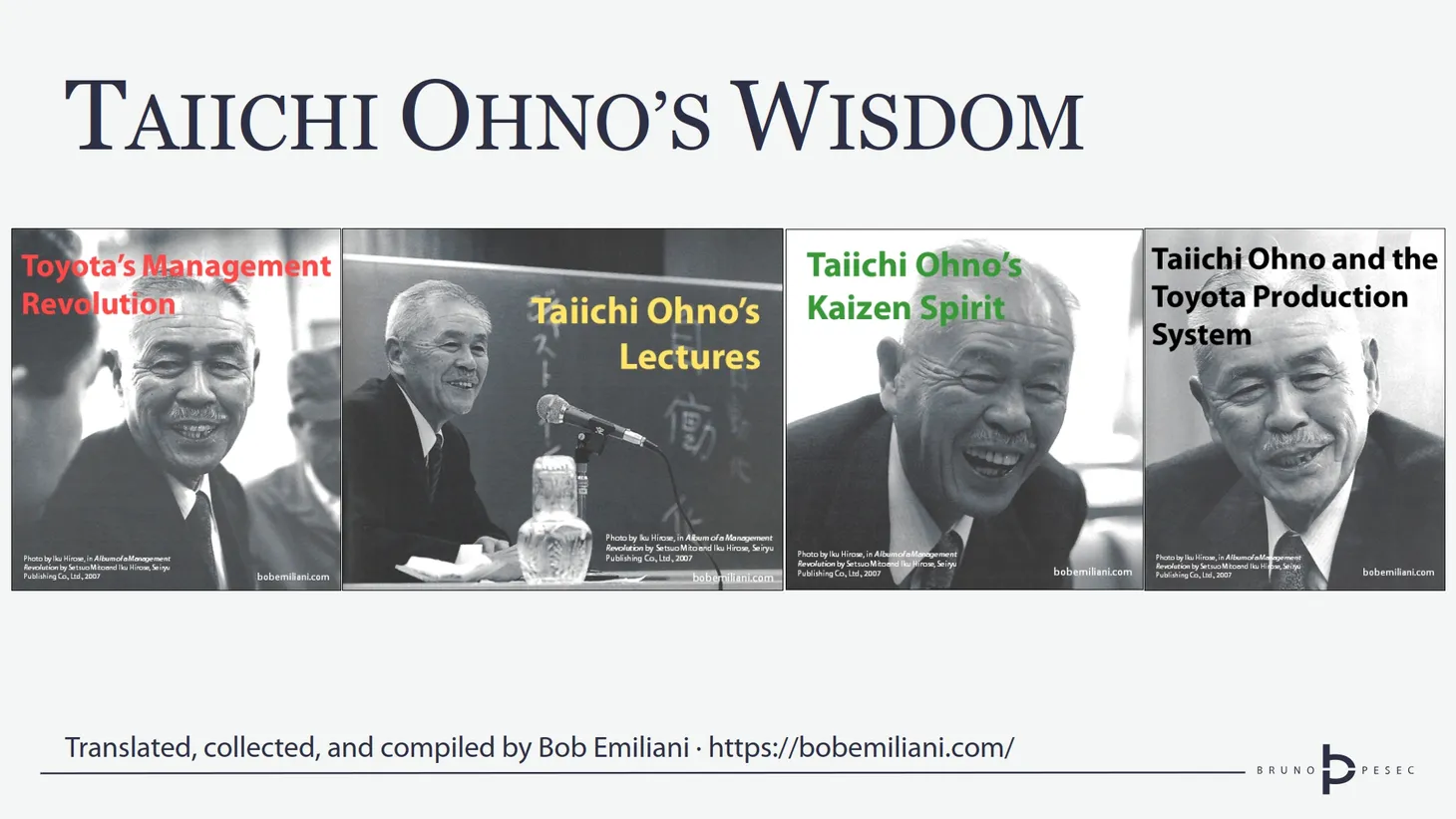

Taiichi Ohno's wisdom

Lessons from the grandmaster.

The value factory

Five ways to supercharge your innovation process using lean practices.

On lean, change, and reflexivity

A conversation with Ron Pereira of Gemba Academy Podcast.

Prioritising ideas is a waste of time

Focus on the flow.

On innovation, learning, and competitive advantage

Disciplined learning = sustained competitiveness.

On learning from Lean Experiments

Capture, analyse, interpret, decide, document.

Test twice, run once

Practice safe experimentation.

On Lean Innovation, Experimentation, and Learning

A conversation with Mark De Jong of The Lean Effect podcast.

The power of visual thinking

How does visual thinking practically help an organization?

Toyota Production System still going strong

At any given moment there are at least hundred things you can improve, but no one except you can do it.

Better banking—everyday in everyway

Banks that are excelling at continuous improvement also have much higher chance of succeeding with innovation.

With eyes wide open

How can you use visualisations to ask better questions?

Lessons from Shigeo and Ritsuo Shingo

What have I learnt from Shigeo and Ritsuo Shingo?

The Lean Presentation

Collection of my posts from The Lean Presentation.

Lean Six Sigma: deployment

How can Lean Six Sigma projects be deployed for maximum effect?

Lean Six Sigma: in-depth comparison

In-depth comparison of Lean and Six Sigma across thirty one elements.

Lean Six Sigma: origin

Is Lean Six Sigma a legitimate methodology or a consultant's trickery?

Lean Thinking: critique

Is lean thinking a copy of the Toyota Way or a standalone philosophy built upon two powerful paradigms of the past?

Lean Thinking: assessing leanness

How can we measure process cycle efficiency, overall equipment effectiveness, and organisational leanness?

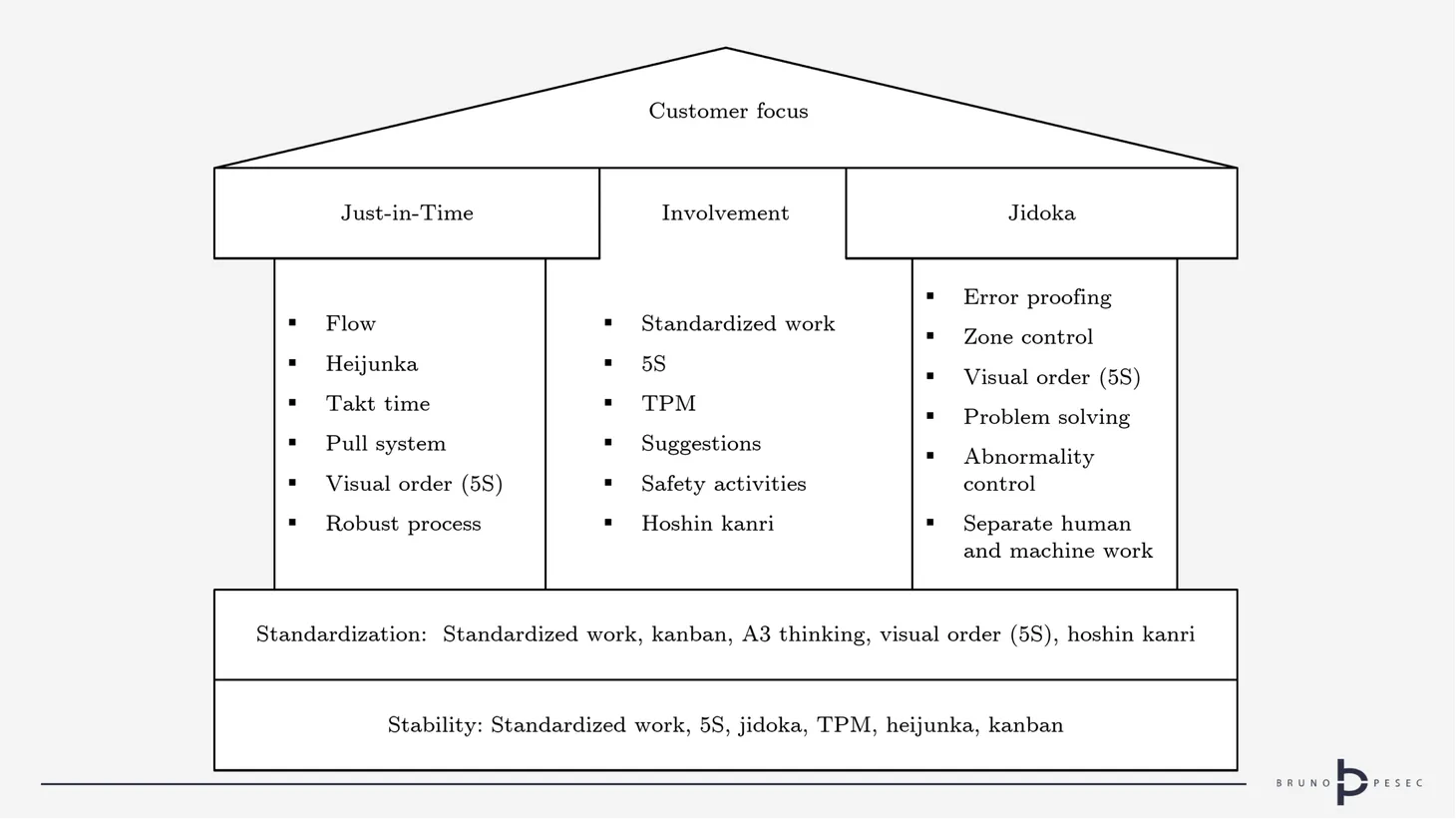

Lean Thinking: principles and tools

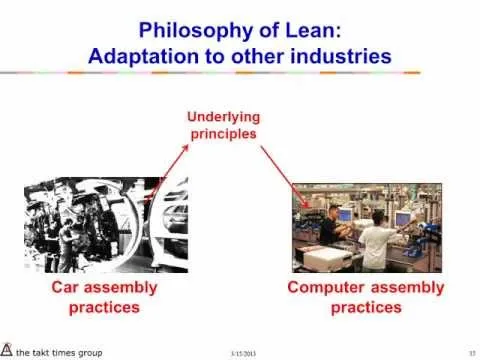

Understanding principles behind the lean thinking is critical for our ability to make a change for the better.

Lean Thinking: origin

A journey from mass manufacturing to Toyota Production System to Lean Thinking.

On Continuous Improvement

Core principles of continuous improvement are (1) process orientation, (2) improving and maintaining standards, and (3) people orientation. What are the fundamental behaviours for developing a culture of improvement?

Mistake Proofing (Poka-Yoke)

Poka-Yoke is a technique for preventing errors from occurring by designing the manufacturing process, equipment and tools in such a way that an operation literally cannot be performed incorrectly.

Quality Management Systems

Comparison of Japanese Total Quality Control, Total Quality Management, Deming’s System of Profound Knowledge, Lean, Business Process Reengineering, and Six Sigma.

How to succeed with lean programs

What is the best way to establish a successful lean programme? What actions should managers undertake in order to contribute to the success of their lean programme?

5S numbers game

Use this numbers game to explain and teach 5S in fun and easy way.

Takt Time, Cycle Time, Lead Time

Watch this video to understand differences between Takt Time, Cycle Time, and Lead Time. After theoretical introduction there are two examples which clearly show how to calculate each of them, and what are they used for.

The Role Of The Plant Manager in Lean

Jim Huntzinger and Michel Baudin discuss the role of the plant manager in Lean implementation.

Introduction to Lean Manufacturing

Learn what Lean Manufacturing is all about.

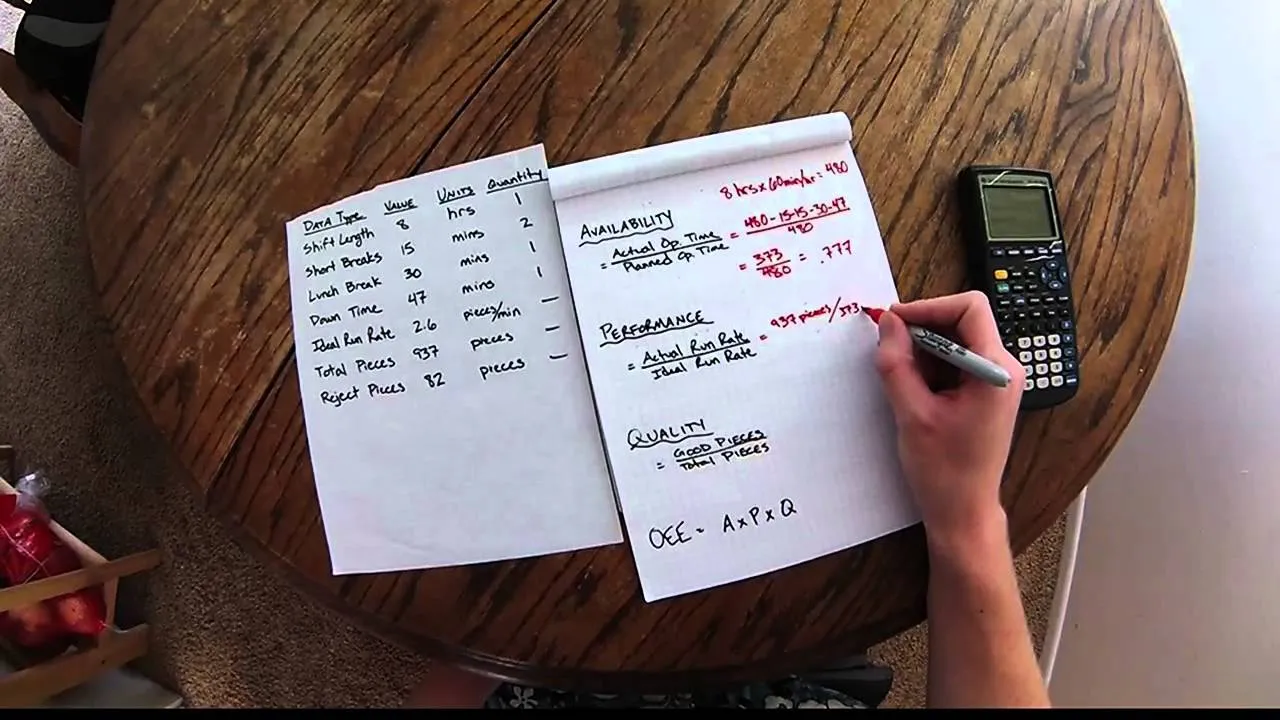

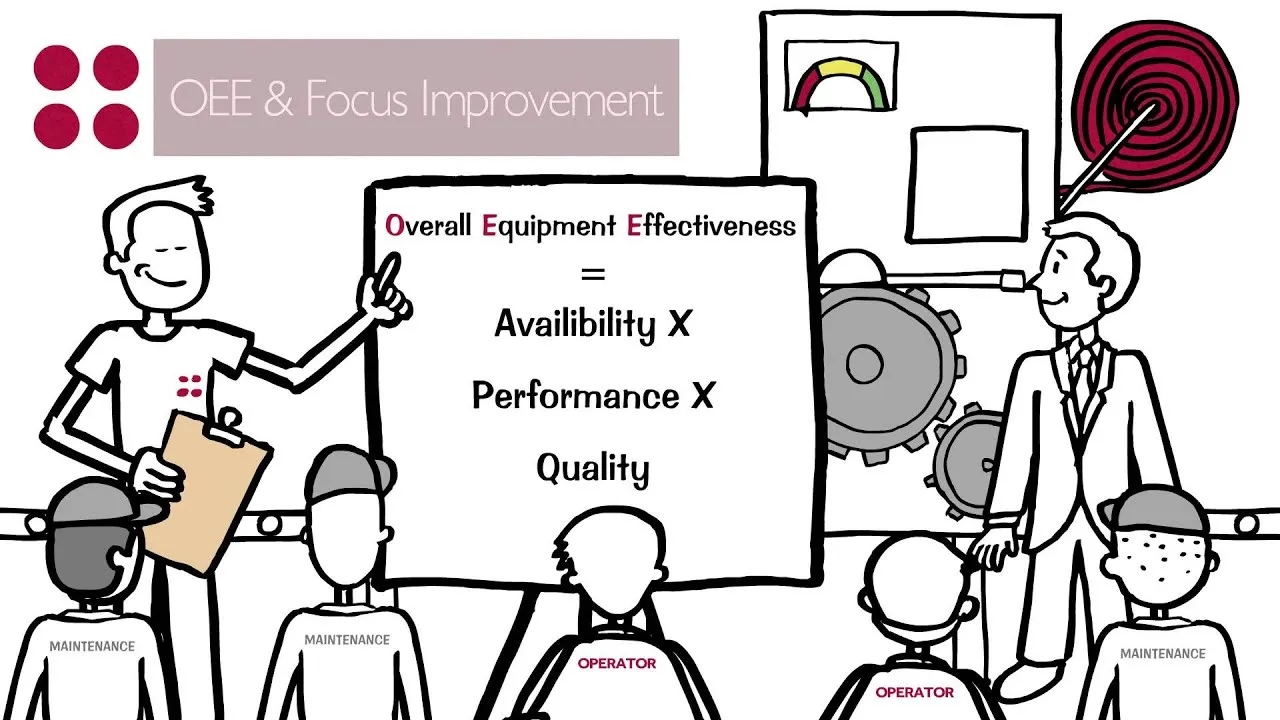

Calculating Overall Equipment Effectiveness

Watch this short example and learn how to calculate Overall Equipment Effectiveness (OEE).

Overview of the Overall Equipment Effectiveness

Overall Equipment Effectiveness (OEE) is a metric which integrates availability, performance and quality metrics. It is also an important part of a successful TPM implementation.

Total Productive Maintenance by Gemba Academy

Learn more about Total Productive Maintenance and how it can support your Lean efforts. It is a combination of preventive maintenance, total quality control, and total employee involvement aimed at achieving zero accidents, defects, and breakdowns.

One-Piece Flow

In this short video by Jeremy of TheLeanWorshop one-piece flow is explained through a simple visual example.

Pull System by Lean Concepts

In this video Isaac-Lowry introduces basic elements of the pull system, kanban, lot sizing, and quick changeover.

Introduction to Total Productive Maintenance

Watch this short video to find out what Total Productive Maintenance (TPM) is and isn’t.

Eight Principles of SMED

Mr. Rogers explains six basic steps of Single Minute Exchange of Die (SMED) basics and its eight principles.

QCO & SMED Overview by Gemba Academy

Quick Changeover (QCO) is an invaluable tool in the pursuit of flow. QCO can be achieved by the system Shigeo Shingo developed in the late 1950-ies called Single Minute Exchange of Die (SMED).

Plug Game by Lean Games

The Plug Game is a manufacturing simulation based on assembling 3 pin plugs, for teach cellular layout, push/pull, one piece flow, kanban, and work balance.

Push vs. Pull

Implementation of the pull system is important part of any lean transformation, and the first step is understanding the difference between push and pull.

Lean in 90 seconds

Have a colleague or friend who would like to know more about Lean but are short on time? Show them this video.

Implementing Lean Six Sigma: The effective integration of two improvement methodologies

This project investigates how can Lean thinking and Six Sigma be effectively integrated in order to deliver superior business results.