Lean Six Sigma: origin

Is Lean Six Sigma a legitimate methodology or a consultant's trickery?

Lean thinking and Six Sigma are widely used by various companies, in various sectors, and are currently referred to as state of the art (Salah et al., 2010).

In this series of articles I will explore the origin of Lean Six Sigma, go into in depth comparison of them, and discuss some deployment mechanism for such projects.

A consultant's race

First publication on the topic of integrated lean thinking and Six Sigma system was in the 2000 (Sheridan, 2000), and the author used the term lean sigma to describe aforementioned system.

The George Group is considered to be the first consultancy company which offered lean thinking integrated with Six Sigma (Salah et al., 2010). In 2002 they published Lean Six Sigma: combining Six Sigma quality with lean speed book (George, 2002), which is considered to be the seminal work in the field.

Integration of lean thinking with Six Sigma is referred to as:

- Lean Six Sigma,

- Lean Sigma,

- Six Sigma Lean, and

- Six Sigma Plus.

Based on the conducted literature review, it can be concluded that Lean Six Sigma is the dominant term. It is defined as follows:

Lean Six Sigma can be described as a methodology that focuses on the elimination of waste and variation, following the DMAIC structure, to achieve customer satisfaction with regards to quality, delivery and cost. It focuses on improving processes, satisfying customers and achieving better financial results for the business. – Salah et al., 2010

Justification

Lean thinking and Six Sigma have often been considered as opposing approaches (Pepper & Spedding, 2010), or were implemented in isolation (Smith, 2003), resulting in conflicting subcultures within the organisation (Bendell, 2006).

Furthermore, one critique is that integration is unjustified and on philosophical level without evidence supporting the integration motive (Bendell, 2006).

Proponents claim that Lean Six Sigma addresses issues that are overlooked by lean thinking and Six Sigma when applied individually, increases organisations improvement chances, and enables transformation into customer focused, employee empowered and flexible organisation (Bhuiyan & Baghel, 2005; Salah et al., 2010; Martin, 2007).

An amalgam

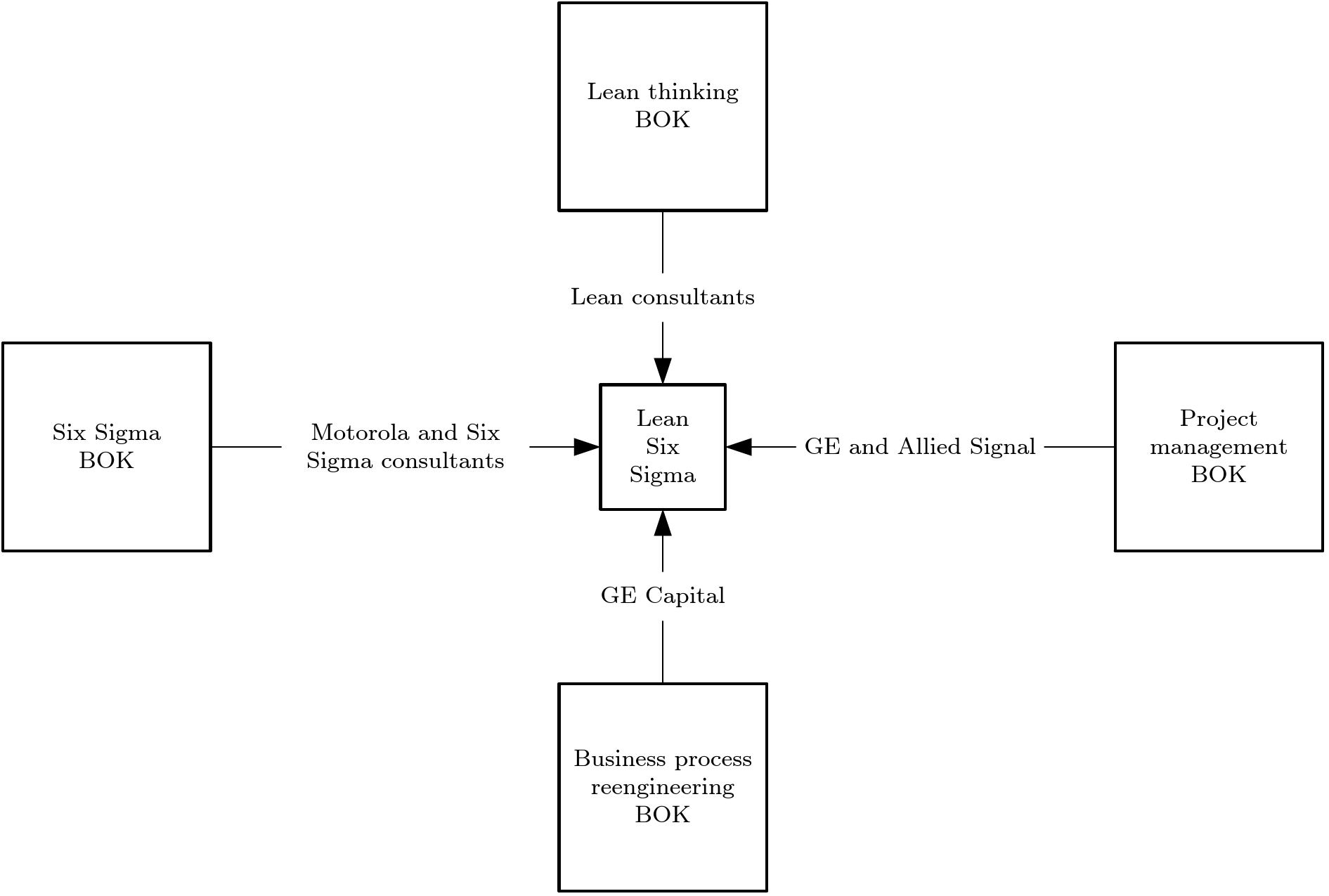

Lean Six Sigma body of knowledge (see figure below) consists of:

- lean thinking body of knowledge,

- Six Sigma body of knowledge,

- business process re-engineering body of knowledge, and

- project management body of knowledge.

I have covered lean thinking extensively in Lean Thinking: origin, Lean Thinking: principles and tools, Lean Thinking: assessing leanness, and Lean Thinking: critique. Six Sigma has been extensively covered in Six Sigma: defined, Six Sigma: deployment and methods, Six Sigma: organisation and roles, and Six Sigma: critique.

Business process re-engineering is defined as the fundamental rethinking and radical redesign of business processes to achieve dramatic improvements in critical contemporary modern measures of performance, such as cost, quality, service, and speed (Hammer, 2003).

A guide to the project management body of knowledge (2004) define project management as the application of knowledge, skills, tools and techniques to project activities to meet project requirements.

Concluding remarks

Based on the above we have to wonder if Lean Six Sigma came to be organically or was it created by consultants who desired to differentiate from those offering Lean or Six Sigma services?

In follow-up articles we will look into differences and synergies between lean thinking and Six Sigma, as well as some deployment models

References

A guide to the project management body of knowledge (PMBOK guide) (3rd ed.). (2004). Project Management Institute.

Bendell, T. (2006). A review and comparison of Six Sigma and the lean organisations. The TQM Magazine, 18(3), 255–262.

Bhuiyan, N., & Baghel, A. (2005). An overview of continuous improvement: From the past to the present. Management Decision, 43(5), 761–771.

George, M. (2002). Lean Six Sigma: Combining Six Sigma quality with lean speed. McGraw-Hill.

Hammer, M. (2003). Reengineering the corporation: A manifesto for business revolution (2nd ed.). HarperBusiness Essentials.

Mader, D. P. (2008). Lean Six Sigma’s evolution. Quality Progress, 41(1), 40–48.

Martin, J. (2007). Lean Six Sigma for supply chain management: The 10-step solution process. McGraw-Hill.

Pepper, M. P. J., & Spedding, T. A. (2010). The evolution of lean Six Sigma. The International Journal of Quality & Reliability Management, 27(2), 138–155.

Salah, S., Rahim, A., & Carretero, J. A. (2010). The integration of Six Sigma and lean management. International Journal of Lean Six Sigma, 1(3), 249–274.

Sheridan, J. H. (2000). ‘Lean sigma’ synergy. Industry Week, 249(17), 81–82.

Smith, B. (2003). Lean and Six Sigma—A one-two punch. Quality Progress, 36(4), 37–41.

This article is a part of Lean Six Sigma series:

Bruno Unfiltered

Subscribe to get the latest posts delivered right to your inbox. No spam. Only Bruno.