Six Sigma: deployment and methods

Learn more about fourteen points for successful deployment of Six Sigma and integrated portfolio of nine Six Sigma methods.

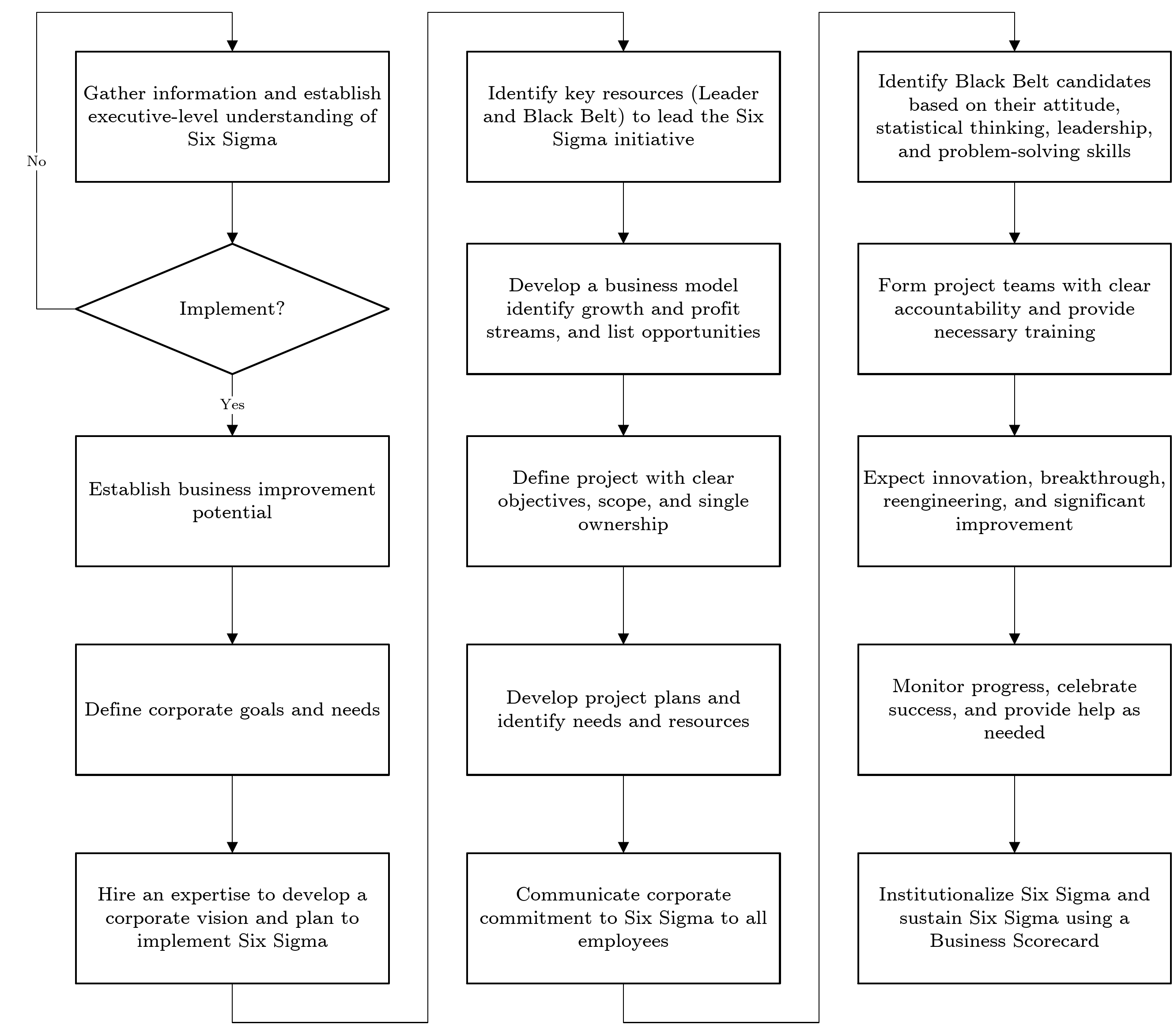

Gupta (2005) asserts that full benefits of adopting Six Sigma can only be achieved if it is treated as strategic initiative for profitability and growth improvement. That indicates that business viewpoint is better at strategic level, while statistical viewpoint is better at operational level. He lists fourteen steps (Figure 1) for successful Six Sigma deployment:

- Gather information and establish executive-level understanding of Six Sigma.

- Establish business improvement potential.

- Define corporate goals and needs.

- Hire an expertise to develop a corporate vision and plan to implement Six Sigma

- Identify key resources (Leader and Black Belt) to lead the Six Sigma initiative.

- Develop a business model, identify growth and profit streams, and list opportunities.

- Define project with clear objectives, scope, and single ownership.

- Develop project plans and identify needs and resources.

- Communicate corporate commitment to Six Sigma to all employees.

- Identify Black Belt candidates based on their attitude, statistical thinking, leadership, and problem-solving skills.

- Identify Black Belt candidates based on their attitude, statistical thinking, leadership, and problem-solving skills.

- Expect innovation, breakthrough, reengineering, and significant improvement.

- Monitor progress, celebrate success, and provide help as needed.

- Institutionalise Six Sigma and sustain Six Sigma using a Business Scorecard.

Methods

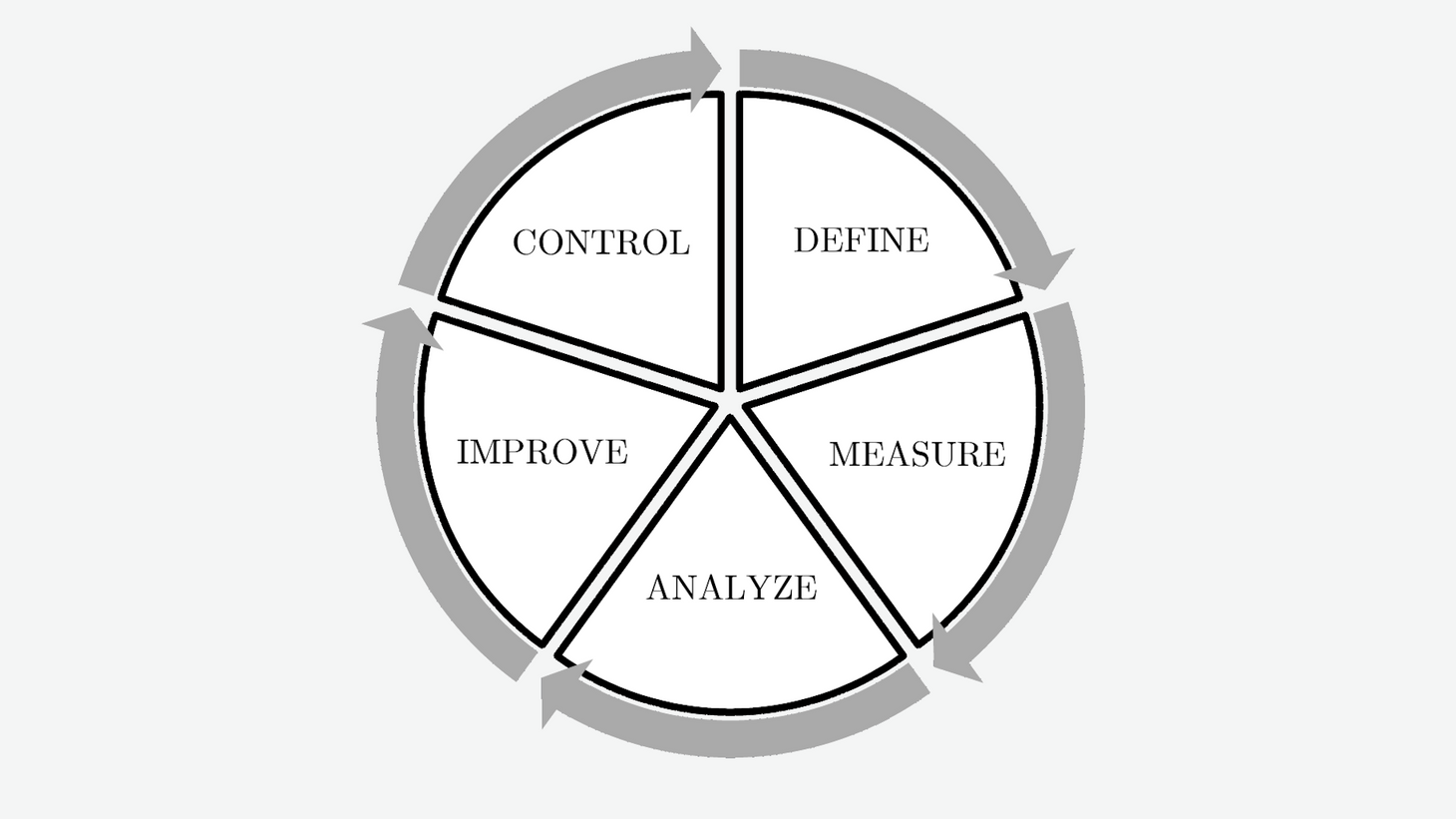

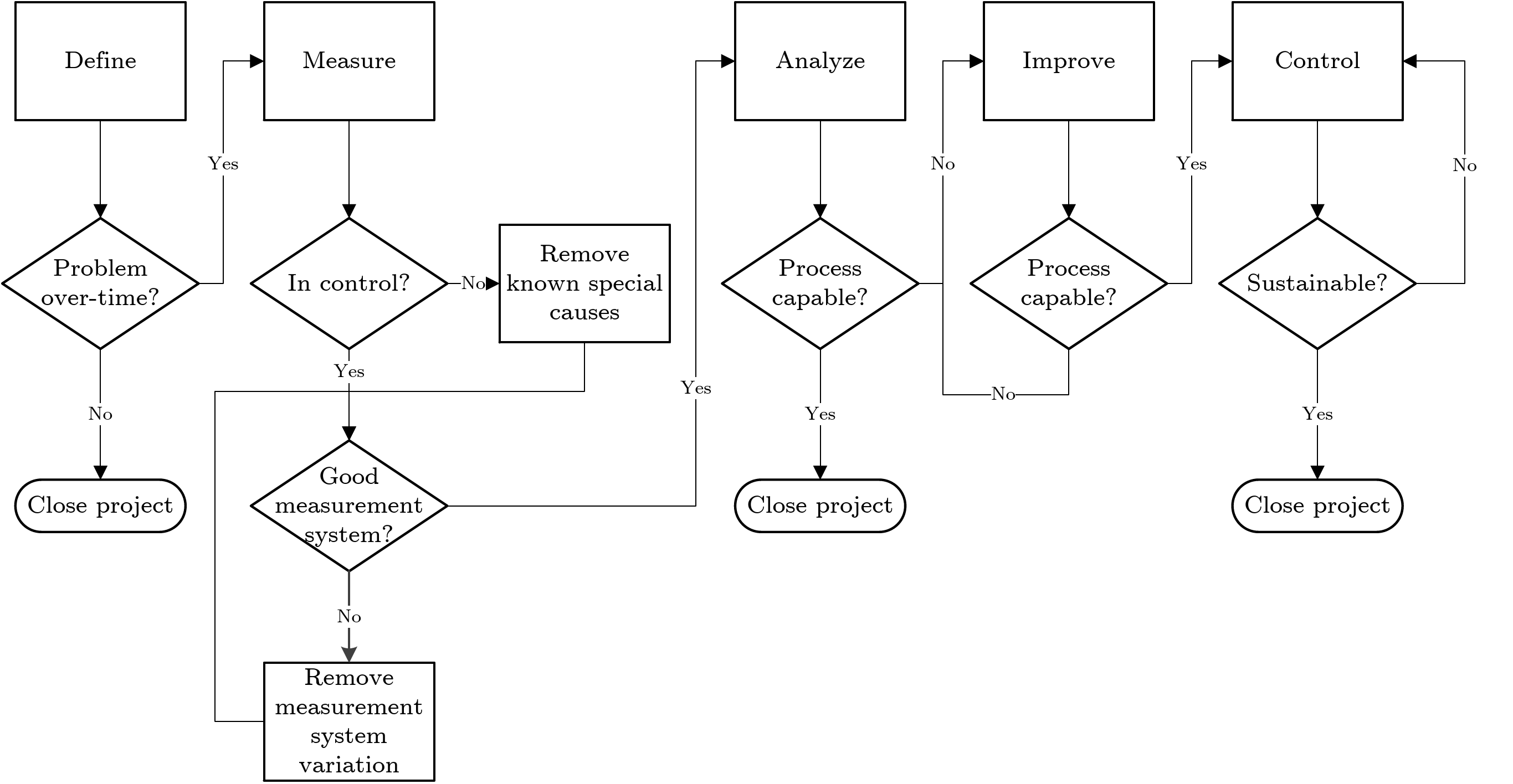

During the first generation Six Sigma (1987–1994), MAIC methodology was used within Six Sigma projects. MAIC stands for four phases that are performed consequently, and was based on PDCA (Plan-Do-Check-Act). In the second generation (1994–2000) D was added, resulting in DMAIC: define, measure, analyse, improve and control. Since 2000, numerous business oriented methodologies which exploit the robustness and rigorousness of DMAIC were devised.

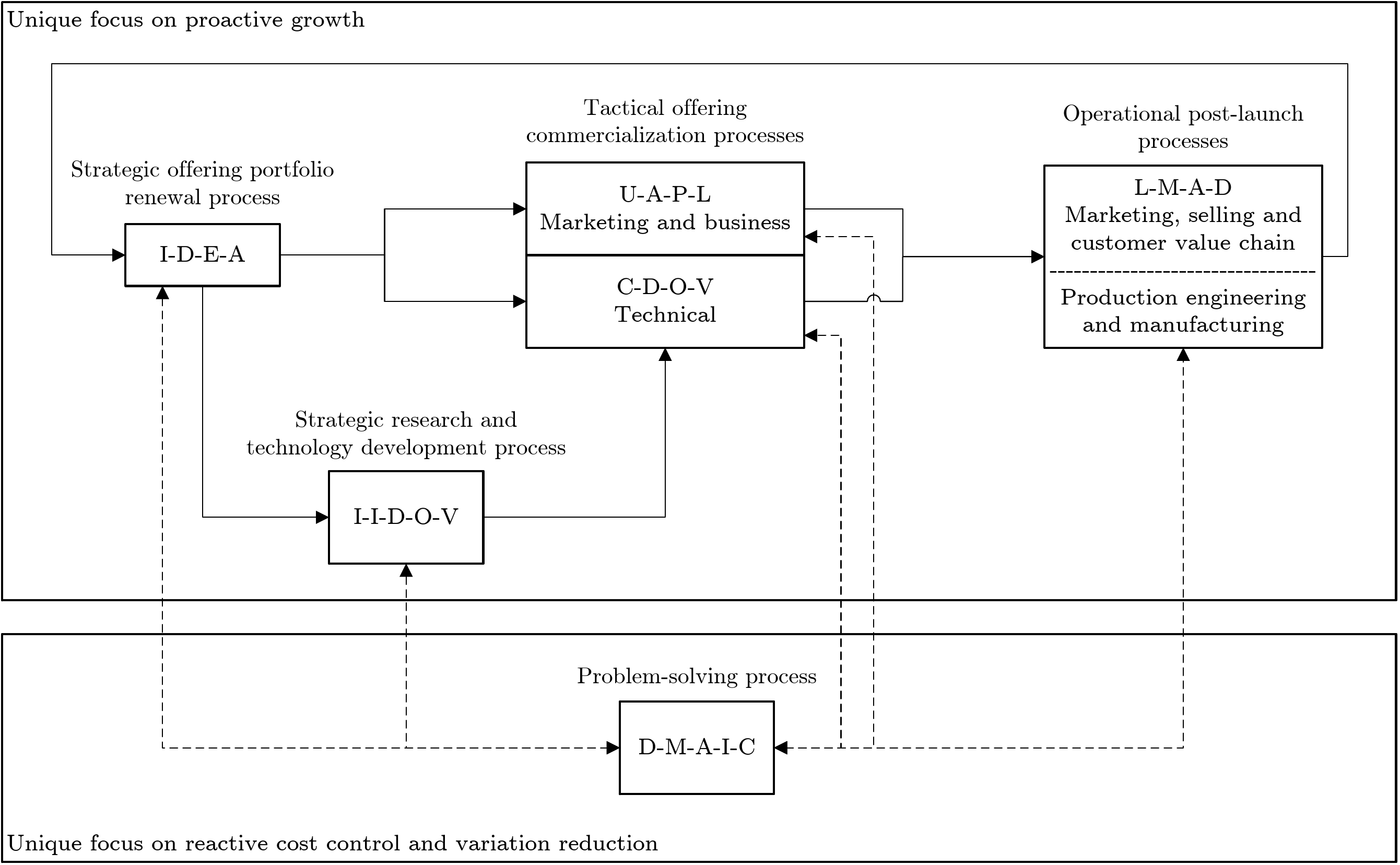

Integrated portfolio of most commonly used Six Sigma methods is presented in Figure 2. Methods were divided in two groups, depending on their focus. Abbreviations and their meaning are presented in table below the figure.

Aforementioned integrated portfolio consists of methodologies that cover business process (in this case product or service) from its inception to its discontinuation. The process flow starts with strategic offering portfolio renewal process, in which organisation identifies its future product or service using IDEA method. Once offering has been identified, funds are reserved for research and technology development process and tactical offering commercialisation processes. IIDOV method is used to guide the research efforts, UAPL method is used in marketing department, and CDOV is used in technical department. Operational post-launch process are guided with LMAD method.

Problem solving process is initiated, namely DMAIC, if problems are encountered in any of aforementioned processes. Besides DMAIC, other variants may be used, depending on the nature of the problem and process: DMAIIC, DMADV or DMEDI.

| Abbreviation | Phases |

|---|---|

| IDEA | Identify - Define - Evaluate - Activate |

| IIDOV | Invent - Innovate - Develop - Optimize - Verify |

| CDOV | Concept - Design - Optimize - Verify |

| UAPL | Understand - Analyze - Plan - Launch |

| LMAD | Launch - Manage - Adapt - Discontinue |

| DMAIC | Define - Measure - Analyze - Improve - Control |

| DMAIIC | Define - Measure - Analyze - Improve - Innovate - Control |

| DMADV | Define - Measure - Analyze - Design - Verify |

| DMEDI | Define - Measure - Develop - Implement |

We shall analyse DMAIC, since all other methods are built on its principles.

DMAIC

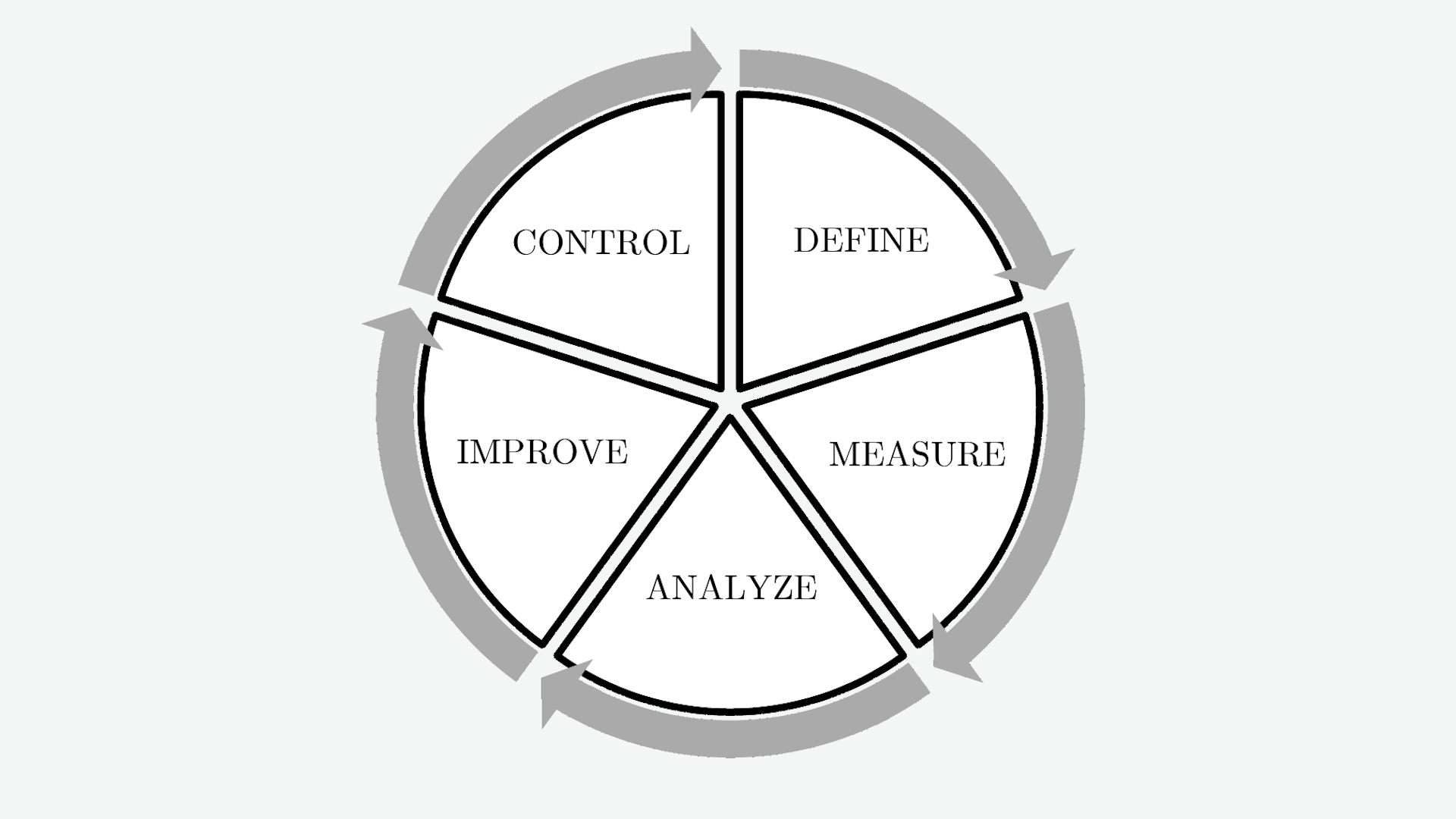

DMAIC is considered to be the core problem solving process in Six Sigma, and is performed in sequential steps (Figure 3). Each step has to be finished prior to proceeding to next step. It should be noted that some activities may be iterative. Hambleton (2008) explains each step as follows:

Step 1: Define. the problem and scope the work effort of the project team. The description of the problem should include the pain felt by the customer and/or business as well as how long the issue has existed. Hence, identify the customer(s), the project goals, and time frame for completion.

The appropriate types of problems have unlimited scope and scale, from employee problems to issues with the production process or advertising. Regardless of the type of problem, it should be systemic --- part of an existing, steady-state process wherein the problem is not a one-time event, but has caused pain for a couple of cycles.

Step 2: Measure. the current process or performance. Identify what data is available and from what source. Develop a plan to gather it. Gather the data and summarize it, telling a story to describe the problem. This usually involves utilization of graphical tools.

Step 3: Analyze. the current performance to isolate the problem. Through analysis (both statistical and qualitatively), begin to formulate and test hypotheses about the root cause of the problem.

Step 4: Improve. the problem by selecting a solution. Based on the identified root cause(s) in the prior step, directly address the cause with an improvement. Brainstorm potential solutions, prioritize them based on customer requirements, make a selection, and test to see if the solution resolves the problem.

Step 5: Control. the improved process or product performance to ensure the target(s) are met. Once the solution has resolved the problem, the improvements must be standardized and sustained over time. The standard-operating-procedures may require revision, and a control plan should be put in place to monitor ongoing performance. The project team transitions the standardized improvements and sustaining control plan to the process players and closes out the project.

We have a selection of tools and techniques for each step:

| Step | Candidate tools and techniques |

|---|---|

| Define | SMART, project charter form (contains problem statement, AS-IS and TO-BE states, business reasons), big $Y$ over time, process map, RACI matrix, VOC/VOB gathering techniques, current process control charts (VOP), stakeholder analysis, CTQ, SIPOC. |

| Measure | $Y=f(X)$ — big $Y$ and little $Ys$, data gathering plan template, control charts, statistical sampling, graphical methods, QFD, detailed process map, revised RACI matrix, MSA, process capability analysis, project charter. |

| Analyze | $Y=f(X)$ — big $Y$ and little $Ys$ and $Xs$, critical gap / step analysis, pareto charts, statistical analysis, correlation and regression, detailed process map, revised RACI matrix, process mapping of critical parameters, process capability analysis, brainstorming, cause and effect diagrams, affinity diagram, hypothesis testing, DOE, FMEA, project charter. |

| Improve | Brainstorming, TRIZ, DOE, FMEA, CBA, pugh concept evaluation, solution selection matrix, force field diagram, QFD, MSA, process capability analysis, detailed process map, future RACI matrix, procedure manual, implementation and transition plan, project charter. |

| Control | Control plan design, control charts, SPC, FMEA, risk analysis, communication pan, stakeholder analysis, MSA, process capability analysis, CBA, training and transition plan, process map, RACI, procedure manuals, scorecard or dashboard, data mining, project charter, new SIPOC. |

Meaning of various abbreviations used in the table above:

- SMART: guide for setting up key performance indicators.

- RACI: Responsibility assignment.

- VOC/VOB: Voice of customer / business.

- CTQ: Critical to quality.

- SIPOC: Suppliers, inputs, process, outputs, and customers.

- QFD: Quality function deployment.

- MSA: Measurement system analysis.

- DOE: Design and analysis of experiments.

- FMEA: Failure mode and effects analysis.

- TRIZ: Theory of inventive problem solving.

- CBA: Cost benefit analysis.

- SPC: Statistical process control.

Concluding remarks

In this post we covered:

- fourteen points for successful deployment of Six Sigma,

- integrated portfolio of nine Six Sigma methods, and

- DMAIC process and selection of tools and techniques for each step.

Follow up article will cover Six Sigma organisation and roles.

References

Gupta, P. (2005). The Six Sigma performance handbook: A statistical guide to optimizing results. McGraw-Hill.

Hambleton, L. (2008). Treasure chest of Six Sigma growth methods, tools, and best practices: A desk reference book for innovation and growth. Prentice Hall.

This article is a part of Six Sigma series:

Bruno Unfiltered

Subscribe to get the latest posts delivered right to your inbox. No spam. Only Bruno.