Lean Six Sigma: deployment

How can Lean Six Sigma projects be deployed for maximum effect?

Four models which integrate lean thinking and Six Sigma have been identified in the organisations. These models are superior— inferior, parallel, serial and simultaneous.

Explanations are as follows:

- Superior—inferior

- Lean—Six Sigma; Six Sigma is applied as tool within lean thinking (for example as a part of Kaizen event)

- Six Sigma—Lean thinking; lean tools are used within Six Sigma deployment (for example, VSM during improve phase)

- Parallel

- Lean thinking and Six Sigma are used within organization to deal with different problems

- Lean thinking and Six Sigma are used within organization to deal with same problems, but separately

- Serial

- Lean thinking and Six Sigma are used within organization to deal with same problems, and are applied in series

- Simultaneous

- Lean thinking and Six Sigma are used within organization simultaneously

Simultaneous model is considered to yield better results than other models (Salah et al. 2010; Pepper & Spedding, 2010).

Deployment of Lean Six Sigma projects

Lean Six Sigma deployment plan includes process focus, organisation structure, measures, rewards and tools (Salah et al. 2010).

Suggested phases for deployment are:

- Comply: the executive team is willing to give Lean Six Sigma a try.

- Commit: a true belief exists across the organisation in the value of Lean Six Sigma.

- Embed: embrace Lean Six Sigma philosophy and drive it beyond the walls of the company.

- Encode: make Lean Six Sigma philosophy a culture.

It should be noted that term philosophy is emphasised, and not methodology. As I've written before, both lean thinking and Six Sigma yield best results when applied thoroughly as philosophy, and are embedded in corporate culture. The same applies for Lean Six Sigma. In addition to aforementioned phases, following institutionalisation steps are proposed by George (2002):

- Start on the right foot: dedicate resources and select the right people and

projects. - Build confidence that Lean Six Sigma is a way of life: publicise results and celebrate, educate and involve employees, train on leadership, leverage existing strengths, focus on all processes (manufacturing and transactional), reinforce corporate values, integrate Lean Six Sigma into strategic planning, create accountability through visibility, communicate effectively and share best practices.

- Extend Lean Six Sigma: use a common language, integrate Lean Six Sigma with business plans, extend it into the supply chain and into the design processes.

Since there is no standard framework for Lean Six Sigma, each organisation should devise its own framework. Summarised list of recommendations when creating Lean Six Sigma framework (Salah et al., 2010):

- be holistic in its nature and have a strategic link,

- use DMAIC as the framework or core structure,

- be tool-based using the best tool that suits the problem faced,

- use both methodologies simultaneously and not paralleled,

- integrate both in a balanced way without a dominant or subordinate one,

- use VSM as its focused platform,

- take into account the differences between the two methodologies,

- include a detailed body of knowledge,

- avoid sub-optimal process improvement and be result focused,

- focus on all processes, manufacturing and transactional,

- use an infrastructure of well trained people representing all of the organisation,

- ensure management, key people commitment and alignment,

- have the criteria for robust project selection,

- have a reward system, motivation, communication system, financial accountability and visibility,

- have a supporting structure of: management systems, standardisation system,

- control application, information technology, sales, marketing and supply chain,

- be extended to suppliers and customers, and

- own the characteristics of an effective change program.

Lean Six Sigma toolbox

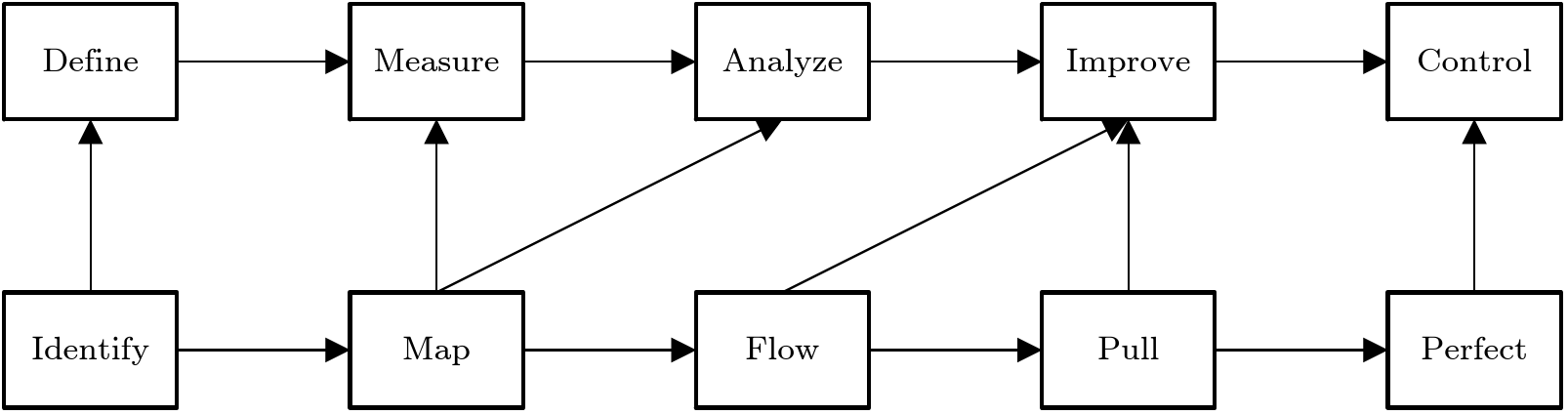

Figure below presents conceptual model which depicts relationship between lean thinking and Six Sigma phases:

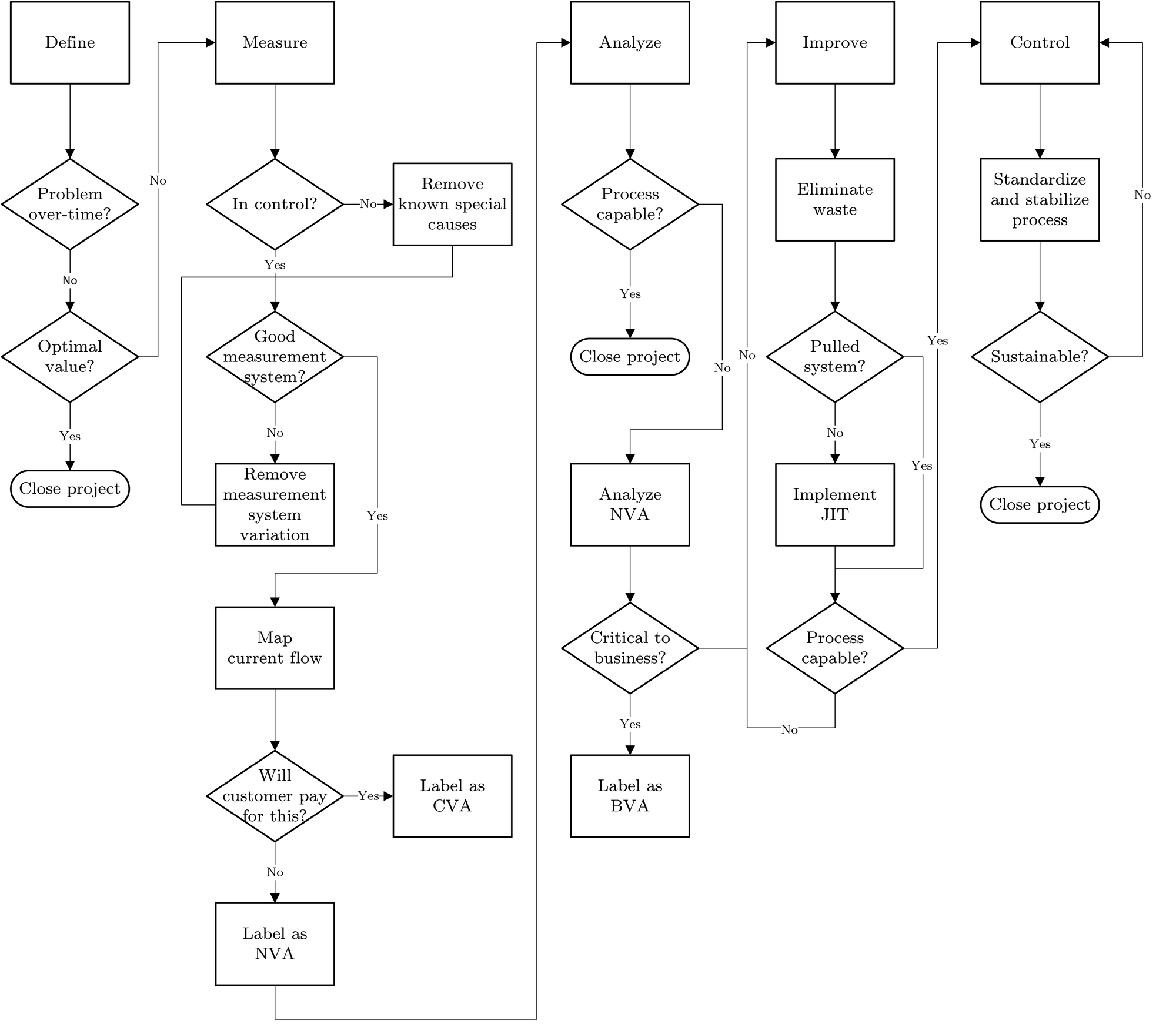

High-level process flow, based on aforementioned concept model, is presented in following figure:

Tools and techniques for each phase can be chosen from either lean or Six Sigma toolbox. Implementation and transformation barriers discussed in Critical barriers for successful Six Sigma implementation apply to Lean Six Sigma as well.

There are no tools unique to Lean Six Sigma.

Concluding remarks

This is a final post in the three-piece Lean Six Sigma series.

Lean Six Sigma originated from lean thinking and Six Sigma. Both of them have roots in TQM – Total Quality Management – but have evolved differently.

Based on my research I believe that this joining was primarily driven by consultants who were looking for ways to differentiate in the market.

This research was done in 2012 for my specialisation project. This blog post was published in 2017.

Looking at Lean Six Sigma, the only conclusion I can draw is that it turned out to be Six Sigma sprinkled with select lean tools.

On the other hand, Lean kept evolving, and has many fertile offspring like Lean Startup, Lean Product and Process Development, and Lean Innovation. It also keeps heavily influencing other movement, for example a whole set of different Agile streams.

References

George, M. (2002). Lean Six Sigma: Combining Six Sigma quality with lean speed. McGraw-Hill.

Hambleton, L. (2008). Treasure chest of Six Sigma growth methods, tools, and best practices: A desk reference book for innovation and growth. Prentice Hall.

Pepper, M. P. J., & Spedding, T. A. (2010). The evolution of lean Six Sigma. The International Journal of Quality & Reliability Management, 27(2), 138–155.

Salah, S., Rahim, A., & Carretero, J. A. (2010). The integration of Six Sigma and lean management. International Journal of Lean Six Sigma, 1(3), 249–274.

This article is a part of Lean Six Sigma series:

Bruno Unfiltered

Subscribe to get the latest posts delivered right to your inbox. No spam. Only Bruno.