Lean

Lean Thinking: critique

Is lean thinking a copy of the Toyota Way or a standalone philosophy built upon two powerful paradigms of the past?

Lean Thinking: assessing leanness

How can we measure process cycle efficiency, overall equipment effectiveness, and organisational leanness?

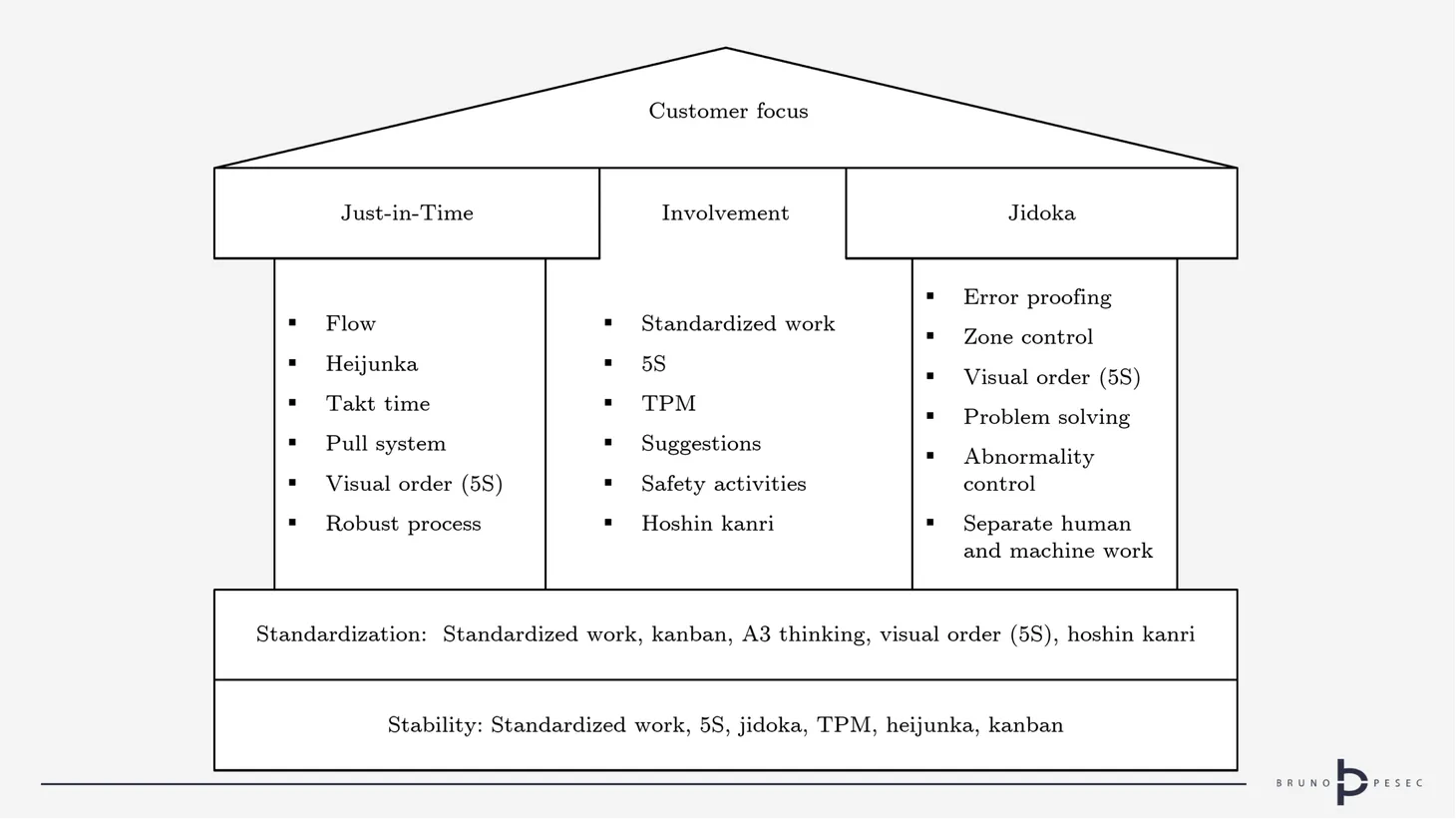

Lean Thinking: principles and tools

Understanding principles behind the lean thinking is critical for our ability to make a change for the better.

Lean Thinking: origin

A journey from mass manufacturing to Toyota Production System to Lean Thinking.

On Continuous Improvement

Core principles of continuous improvement are (1) process orientation, (2) improving and maintaining standards, and (3) people orientation. What are the fundamental behaviours for developing a culture of improvement?

Mistake Proofing (Poka-Yoke)

Poka-Yoke is a technique for preventing errors from occurring by designing the manufacturing process, equipment and tools in such a way that an operation literally cannot be performed incorrectly.

Quality Management Systems

Comparison of Japanese Total Quality Control, Total Quality Management, Deming’s System of Profound Knowledge, Lean, Business Process Reengineering, and Six Sigma.

How to succeed with lean programs

What is the best way to establish a successful lean programme? What actions should managers undertake in order to contribute to the success of their lean programme?

5S numbers game

Use this numbers game to explain and teach 5S in fun and easy way.

Takt Time, Cycle Time, Lead Time

Watch this video to understand differences between Takt Time, Cycle Time, and Lead Time. After theoretical introduction there are two examples which clearly show how to calculate each of them, and what are they used for.