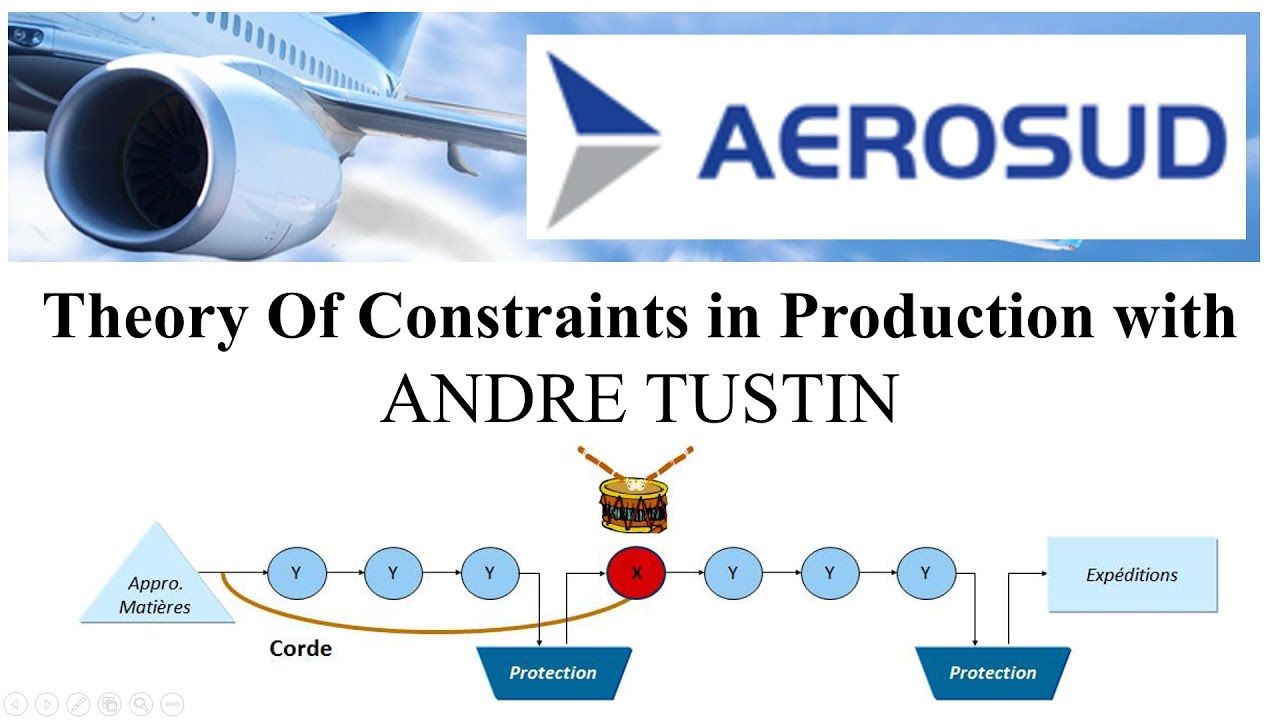

Theory of Constraints in production within Aerosud Aviation

Aerosud Aviation began their TOC implementation in 2014. Learn more about their replenishment solution, buffer management system, and visual warning system.

Learn how Aerosud Aviation applied TOC to their production.

Aerosud Aviation, with the help of Marris Consulting, began their TOC implementation in 2014. In this video they focus on TOC implementation in production, and discuss:

- Replenishment solution

- Buffer management system

- Visual warning system

In another video you can learn more about how Aerosud Aviation implemented Critical Chain Project Management (CCPM). Especially interesting is their implementation of visual system:

“At Aerosud a visual means of focus has been implemented through the use of a significant object, known as a “mascot”. A “mascot” is given to the resource performing the task on the critical chain, upon completion of this task the mascot is then moved to the resource performing the next task on the critical chain. In so doing the “mascot” moves along the sequence of tasks making up the critical chain. With a “mascot” on his/her desk, the resource must only work on the critical chain task, in so doing multi-taking is eliminated and focus is ensured. Aerosud has implemented the use of several fun “mascots” to further visually enhance the significance of the critical chain task.”

You can see more videos by Marris Consulting here.

This post was originally written for The Lean Presentation.

Bruno Unfiltered

Subscribe to get the latest posts delivered right to your inbox. No spam. Only Bruno.