Lean

The Role Of The Plant Manager in Lean

Jim Huntzinger and Michel Baudin discuss the role of the plant manager in Lean implementation.

Introduction to Lean Manufacturing

Learn what Lean Manufacturing is all about.

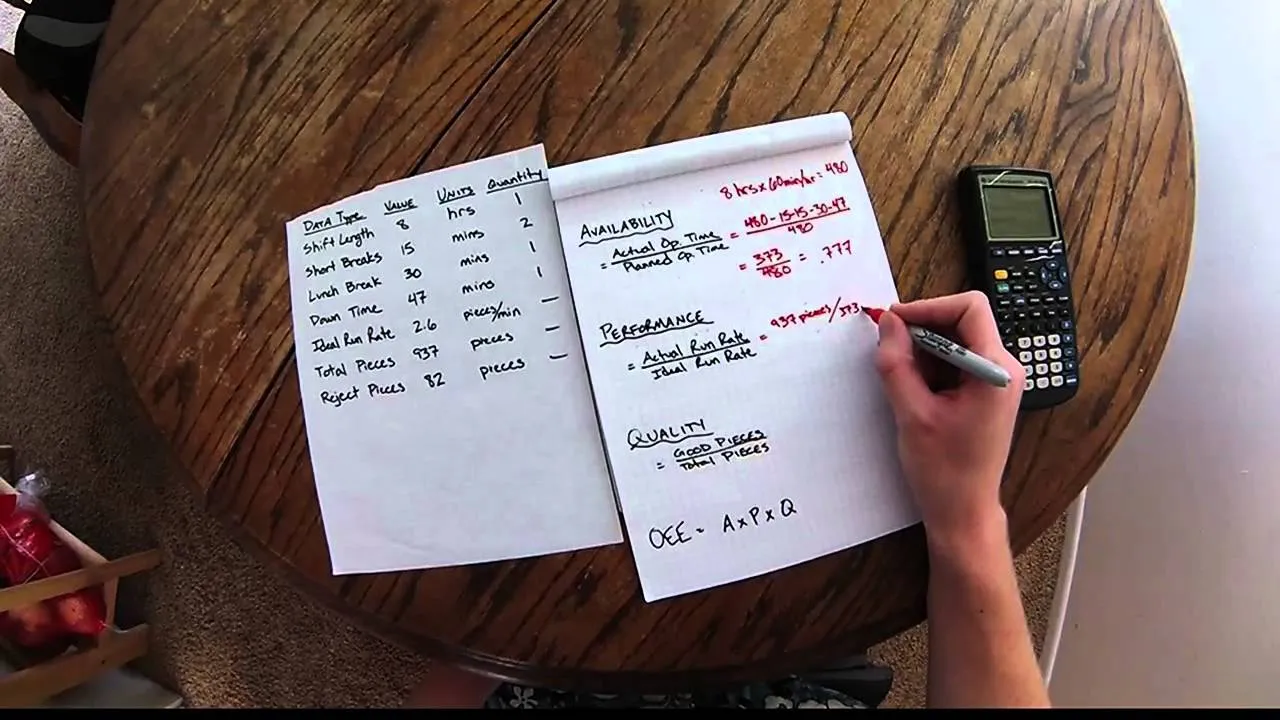

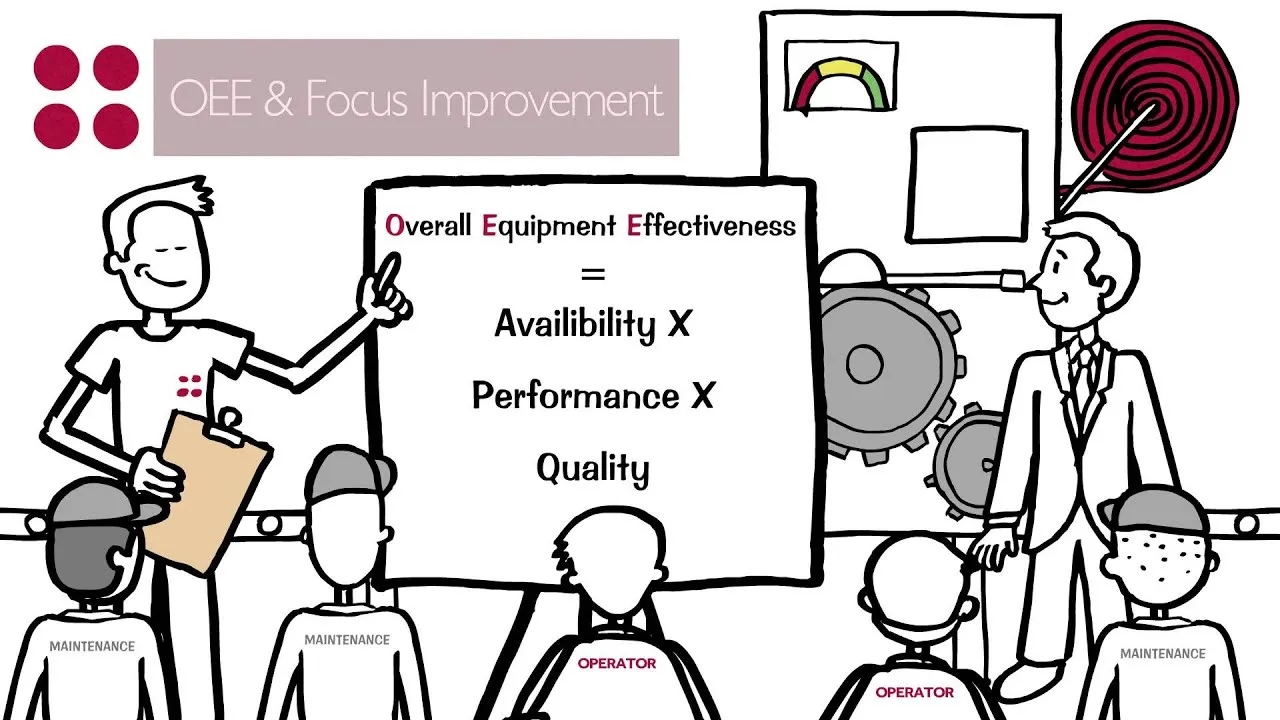

Calculating Overall Equipment Effectiveness

Watch this short example and learn how to calculate Overall Equipment Effectiveness (OEE).

Overview of the Overall Equipment Effectiveness

Overall Equipment Effectiveness (OEE) is a metric which integrates availability, performance and quality metrics. It is also an important part of a successful TPM implementation.

Total Productive Maintenance by Gemba Academy

Learn more about Total Productive Maintenance and how it can support your Lean efforts. It is a combination of preventive maintenance, total quality control, and total employee involvement aimed at achieving zero accidents, defects, and breakdowns.

One-Piece Flow

In this short video by Jeremy of TheLeanWorshop one-piece flow is explained through a simple visual example.

Pull System by Lean Concepts

In this video Isaac-Lowry introduces basic elements of the pull system, kanban, lot sizing, and quick changeover.

Introduction to Total Productive Maintenance

Watch this short video to find out what Total Productive Maintenance (TPM) is and isn’t.

Eight Principles of SMED

Mr. Rogers explains six basic steps of Single Minute Exchange of Die (SMED) basics and its eight principles.

QCO & SMED Overview by Gemba Academy

Quick Changeover (QCO) is an invaluable tool in the pursuit of flow. QCO can be achieved by the system Shigeo Shingo developed in the late 1950-ies called Single Minute Exchange of Die (SMED).